Table of Contents

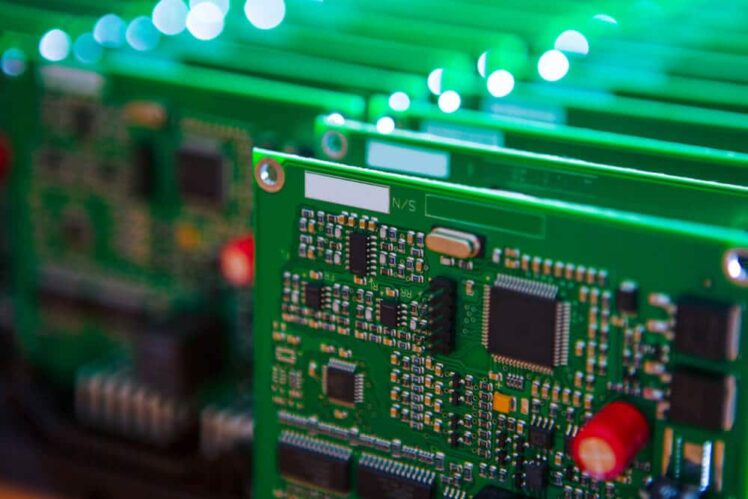

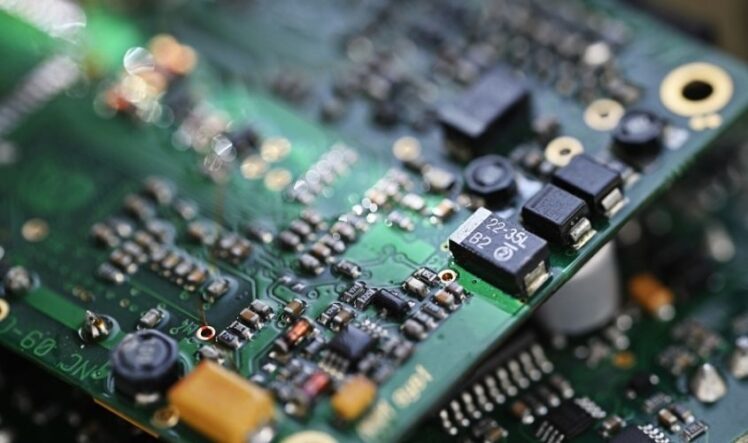

Not a lot of us are fully aware of just how integral PCBs are in the modern world. They are in everything – from our cell phones to our cars – and they play a vital role in the functioning of many of our most important devices. Given their ubiquity, it’s no wonder that the manufacture of these tiny boards has become a big business.

But while the mass production of printed circuit boards is a relatively straightforward process, the same cannot be said for their prototypes. The development of a new PCB prototype is a delicate and often painstaking task that requires a great deal of expertise and experience.

Why is this so? Why are prototypes of printed circuit boards so important? Well, that’s what we’ll try to find out today.

What Is PCB Prototype Manufacturing And Why Is It Important?

A printed circuit board, or PCB, is a thin piece of insulating material onto which conductive pathways are etched. These pathways connect various electronic components to each other, allowing them to communicate and share power.

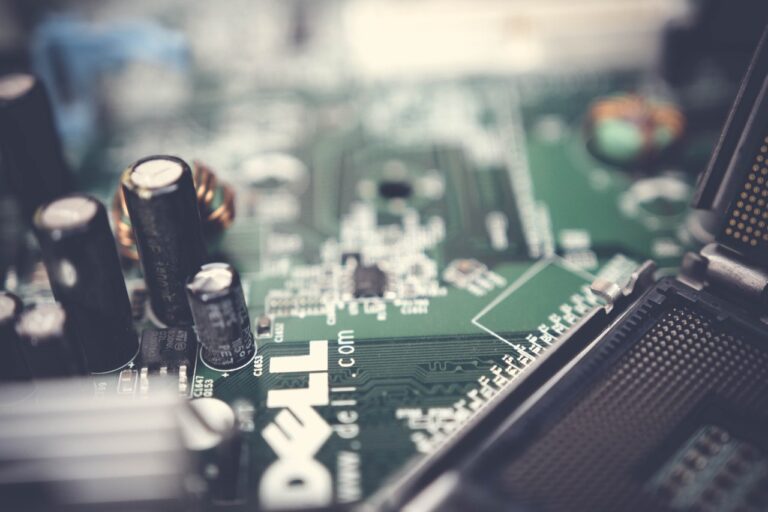

PCB prototype manufacturing is the process of creating these prototypes. This usually involves using computer-aided design (CAD) software to create the necessary pathways on the board. Once the design is finalized, it is sent to a prototype manufacturer who will produce the actual boards.

There are several reasons why prototype PCB manufacturing is so important. For one thing, it allows engineers to test out new designs before mass production begins. This is crucial for catching any potential errors or problems that could arise during production.

It also allows for modifications to be made to the design before it goes into mass production. This can save a lot of time and money down the line, as it is much easier and cheaper to make changes to a prototype than it is to a mass-produced board.

Finally, prototype PCB manufacturing helps to ensure that the final product is of the highest quality possible. By testing and refining the design before it goes into production, prototypes can help to weed out any potential issues that could cause problems down the line.

“In other words, prototype PCB manufacturing is a vital part of the development process for any new printed circuit board. Without it, many of the products that we rely on every day would simply not be possible”, as told by designers and engineers over at https://uetpcb.com/.

But, was it always that way?

How PCB Prototype Manufacturing Has Evolved Over The Years?

While the importance of prototype PCB manufacturing has remained constant over the years, the process itself has undergone a number of changes and refinements.

One of the biggest changes has been the introduction of CAD software. This has made it much easier for engineers to design prototypes, as they can now do so on their computers without having to worry about the physical constraints of the manufacturing process.

This has led to a decrease in the amount of time and money needed to develop a new prototype. It has also allowed for more complex designs to be created, as the software can handle intricate pathways with ease.

Another big change has been the introduction of flexible and flex-rigid PCBs, as well as HDI PCBs back in the mid-90s. These new board types have pushed the boundaries of what is possible with PCBs, opening up new possibilities for designers.

Finally, the last few years have seen a big push towards miniaturization. This has been driven by the ever-increasing demand for smaller and more compact and complex electronic devices. As a result, manufacturers have had to develop new ways or adapt existing technologies to produce smaller prototypes.

A Glimpse Into The Future

It is clear that PCB prototype manufacturing plays a vital role in the development of new printed circuit boards. It allows engineers to test out new designs, make changes to the design before production begins, and ensure that the final product is of the highest quality possible.

As electronic devices continue to get smaller and more complex, the importance of PCB prototype manufacturing is only going to increase. We can expect to see even more changes and refinements to the process in the years to come, as manufacturers strive to keep up with the latest market demands and fresh ideas.

So, what does the future hold for PCB prototype manufacturing? Only time will tell, but one thing is for sure – the advantages that PCB manufacturing offers will always stay the same.

The Advantages Of PCB Prototypes

Let’s check them out!

Reduced Manufacturing Time And Cost

The biggest advantage of using a prototype PCB is the time and cost savings that it offers. By working with a prototype manufacturer, you can get your boards made faster and at a lower cost than if you were to go through the traditional manufacturing process.

This is because prototype manufacturers have all of the latest tools and technologies at their disposal, which they can use to quickly and accurately produce your boards. They also have a team of experienced engineers who can help you to optimize your design for manufacturing, which can further reduce the time and cost of production.

Easier To Identify And Fix Errors

Another big advantage of prototype PCBs is that they make it much easier to identify and fix errors in your design. This is because you can catch errors early on in the process before they have a chance to affect the final product.

This can save you a lot of time and money in the long run, as you won’t have to waste time and resources fixing errors that could have been easily avoided.

Individual Component Testing

Another big advantage of prototype PCBs is that they allow for individual component testing. This means that you can test out each individual component of your design to see how it works and interacts with the other components before making any changes to the design.

This can save you a lot of time in the development process, as you won’t have to waste time and resources testing out components that don’t work well together.

Greater Design Flexibility

Another advantage of prototype PCBs is that they offer greater design flexibility. This is because you can make changes to your design during the prototype stage without incurring any additional costs or time delays.

This means that you can experiment with different ideas and concepts, which can lead to a better-designed and more innovative final product.

Conclusion

As you can see, there are many advantages that PCB prototype manufacturing offers. If you are looking to develop a new printed circuit board, then working with a prototype manufacturer is a great way to save time and money, while also ensuring that your final product is of the highest quality possible.